Factory Automation

It is our strong belief that current millennial technological advantage has opened up innumerable possibilities of production unit profitability, efficiencies and productivity through usage of robotics, sophisticated devices and machinery. Our operations include elementary selection, sorting, vision check, customized arm tool building, designing comprehensive work cells, for high-tech manufacturing set-up.

- Products used are comprehensive, shelf-off, industry standardized, superlative technology based.

- Integrated robotics platform with usage of 3-dimension and 2-dimension scanning.

- Easy operations in varied industrial needs such as food processing, hand-picking, bin picking, speed picking, materials processing and much more.

Features :

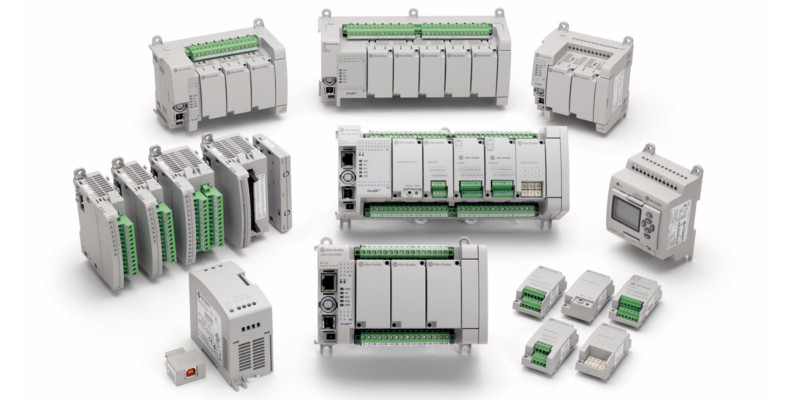

1. Micro PLC suitable for Small applications

- Customized proven systems for the needs of the type of industry, with documentation guidelines for every single Unit.

- Long lasting, stable platform for decades and even centuries of operations.

- Impeccable noise immunity.

- Easy source-code program debugging.

- Easy collaborative communication with other production devices like transmitters, valves, relays, actuators, motor starts, HMI, VDFs etc.

- Most suited for operations in extreme industrial environmental conditions such as marine, airplanes, tanks etc.

2. Compact HMI with Data logging

- Simplistic and effective Compact HMI installation, with central, single node control configuration and installation.

- Augmented security within system, having support for O/S including, Windows UAC, Windows 8.1, other Windows Server versions.

- Optimal Alarm Analysis and Shelving capabilities.

- Navigation is now a breeze, with easy, efficient GUIs using tools such as buttons, menus, tabs and lists.

- Enhanced latest, situation investigation that includes tools like alarm-state, coloured trend curves.

3. Easy programming with Workbench

- Customized, on-call programming and technical support for varied and every single unit of a production unit.

- Provide comprehensive, back-bone Programming support for efficiency, effectiveness, viability and operations of entire automated factories.

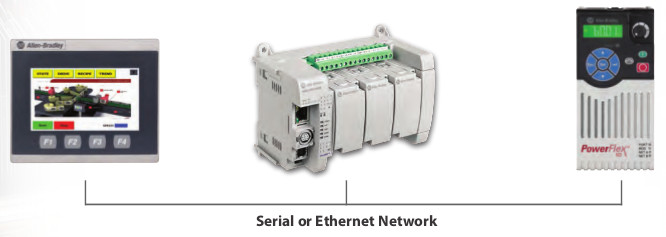

4. Ethernet / Serial Communications

- Usage of latest, high-speed cable and optic fibres.

- Long distance communication made easy.

- Usage of standard access points such as best-in-class Switches, Routers, access points, Hubs, etc.

- Wielding the power of multiple nodes.

- Best interoperable technology

5. Sensors

- Designed in reliable compact, flexible methodologies with nil internal bearings.

- Accurate measuring capabilities for dynamic, speed and position-detection application requirements.

- Innovative design suited for millennial production units.

Features :

Language Support & Switching

- Display information in local languages including French, German, Italian, Portuguese, Spanish and Simplified Chinese for operator and support personnel

- Configure numeric, date and time format for each locale

Alarming

- Alert operators with alarm messages that include embedded variables

- Review alarm status, history and time/date of equipment events even after power cycle

Recipe

- Upload and download parameter settings with a single operation

- Save recipes in .csv format for backup or offline modification

Communications

- Communicate to micro controllers (MicroLogixTM, Micro800®) and other devices using serial (RS232, RS422/485)

protocols and Ethernet - Multi-communication protocols include Modbus RTU and Modbus/TCP

Landscape and Portrait Modes

- Configurable to support both landscape and portrait applications

PanelView 800 Graphic Terminals

- High-speed processor

- High-resolution display with LED backlight

- Built-in memory