Programmable Logic Controller (PLC)

Establishing entire imperatives for a fully functional Production Unit!!!

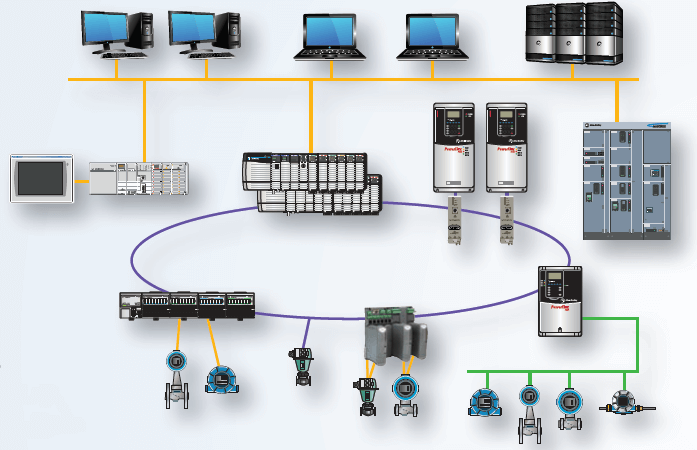

- GraviTech’s emphasis has always been to bring together information sourced from different points of a Production unit into a single Control Room source from where they can be extracted.

- Our Research, Design, Development and Implementation methodologies adhere to and are compatible to all European and other international Standardizations.

- Based on the customer’s requirements, conditions and needs, we source your implementation platforms from just across the best of the industry.

Features

1. Simplex / Redundant CPU Systems

Our engineering methodologies use configuration techniques that provide the most accurate availability through :

- State-of-art Simplex PLCs

- Most reliable PLC configuration touching 99% reliability

- Redundant CPU System installation ensure accurate performances for all, even critical uptimes.

2. High Speed Communication Network

PLC System installation practices in GraviTech ensure availability adequate, high-speed network options. These include :

- Most robust Ethernets and serial

- Abundant protocols

- Sufficient ports needed within the Client’s PLC System.

3. Distributed Input / Outputs

Absolute integrated processing of multiple site data with modular flexibility is now a practical reality.

- PLC designs ensure a variety of I/O options.

- Includes analogue / digital channels, counters, temperature measures and much more.

4. Up to 128,000 I/O's

Technical and connectivity capabilities of our PLC knowledge-base render :

- Connection to remote racks with increased number of I/O cards.

- Handling capacity far more than the base unit capacity;

- Spanning across significant physical distances.

5. Easy Line Integration

Planning your production lines is now as easy as a breeze :

- Application of latest techno-competency within packaging industry or otherwise.

- Our portfolio includes highly precise dynamic checkweighers;

- Other complete ingredients that suit your production line accurately.

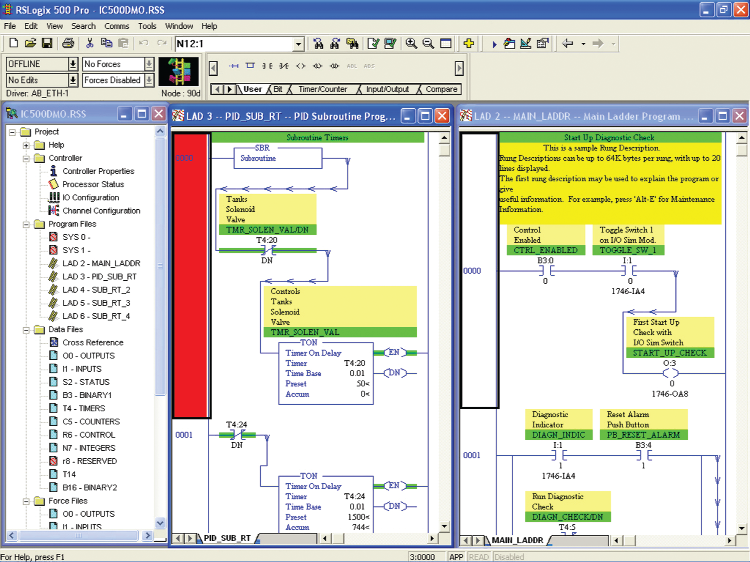

6. Tag based Architecture

The freedom that you’ve always needed to actually control the controller!!!

- Freely perform your memory mapping, using dynamic mapping of data types;

- Making your documentation a breeze too.

7. Interactive HMI systems

Our adept PLC interface designs facilitate :

- Harnessing the power of HMIs for boosting your production line efficiencies.

- Leveraging on the aspects of Control systems and visualization.

- Complete centralized remote access and integrated PLC environment.

8. Advanced Programming Languages

GraviTech’s programming techniques and choice of programming languages are :

- Specific and customized to each requirement of each client.

- View the power of advanced programming including execution of specific functions.

- Fundamental ladder logic clocked flip-flop, execution of PLC shots operations to flip-flop edge triggering.

9. Reporting and Historian Data Collection

Availability of an array of report options.

- Corresponding format integrated into our PLC System designs.

- Play a vital part especially while you troubleshoot.

- Augmented by detailed, structured documentation for quick references whenever required.